Tank Container Service

Home

Tank Container Service

Cleaning

The facility is equipped with the latest state-of-the-art Groninger automated tank cleaning system, featuring multiple bays dedicated for ISO container tanks and a separate bay for road tankers. Multiple rotor jets per bay ensure the fastest turnaround time for your containers.

We have automated drying equipment via the Groninger drypack which guarantees no moisture will be left over after the cleaning and washing cycle allowing us to immediately seal and load container for delivery if required.

Steam cleaning is one of our areas of specialization. It is a multi-purpose appliance, mess free and environmentally friendly. Kosher + Halal Washes : Our automated system allows us to customize the wash cycles to fit the needs of specialised food grade cargoes.

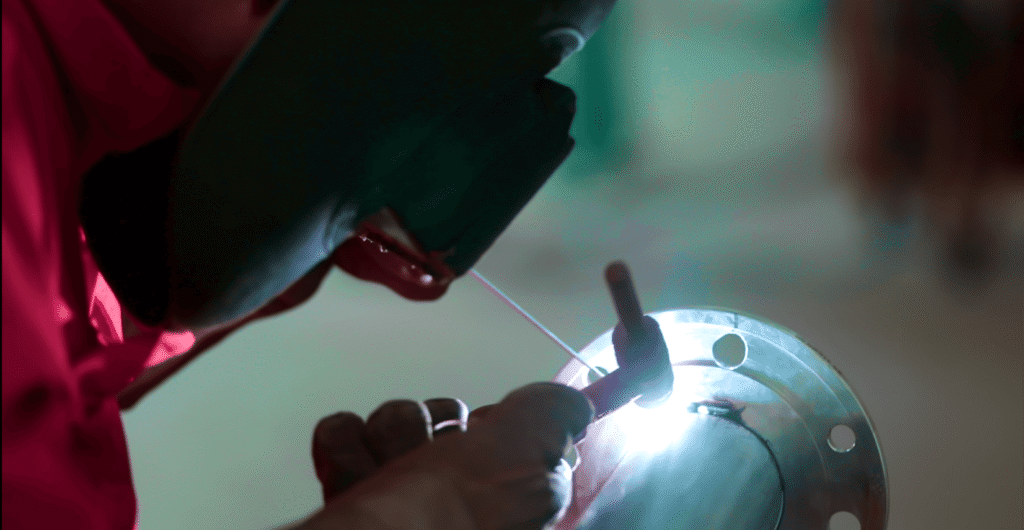

Repair

Repairing tank containers is one of the main activities at Bayarea Terminals tank depot. Having our own repair and testing shed allows us to be at your service round the clock, providing in-service inspections and repair work for your tanks to ensure they remain in peak operating condition.

Our dedicated team works with precision, maintaining global safety and quality standards while minimizing downtime. All our welders are certified and highly skilled, ensuring every job meets the highest industry standards.

We aim to deliver reliable, efficient, and long-lasting repair solutions for every tank we handle. All our welders are certified and highly skilled, ensuring every job meets the highest industry standards.

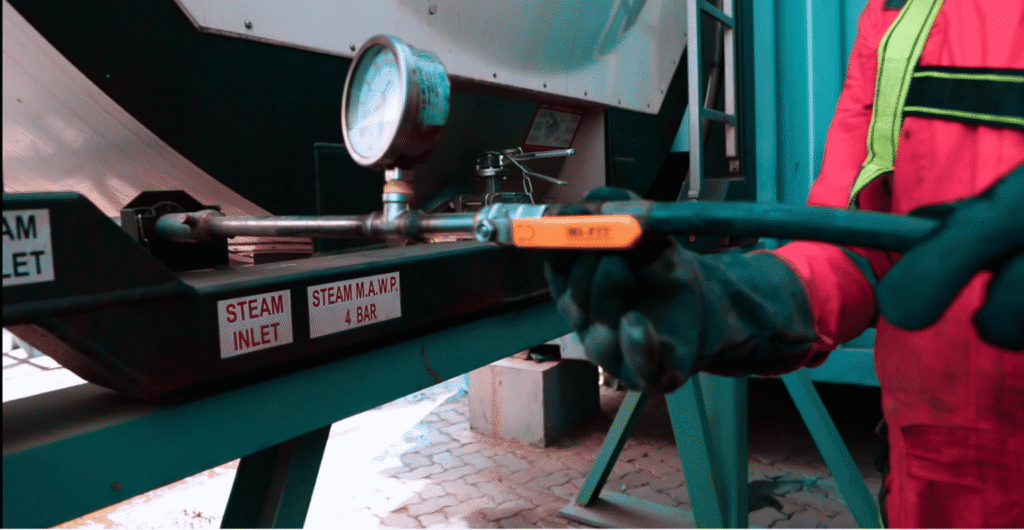

Testing

At BayArea Terminals, we ensure that every ISO tank container meets the highest standards of safety, integrity, and regulatory compliance through our comprehensive testing services. Our advanced testing protocols are designed to certify tanks for hazardous and sensitive cargo transport—giving you complete confidence in your logistics chain.

Our Testing Capabilities

✅ 2.5‑Year & 5‑Year Periodic Testing

✅ Leak Testing (Pre‑trip & In‑service)

✅ Pre‑Trip Inspection (PTI)

✅ Degassing and Vacuuming

Whether you need scheduled statutory testing, pre‑shipment verification, or specialized NDT, BayArea Terminals delivers accuracy, reliability, and full compliance—so your tanks are always road‑, rail‑, and sea‑ready.

Storage and Handling

The entire yard at Bayarea’s facility is completely paved, ensuring smooth, stable, and safe operations throughout all weather conditions. A high-capacity Reach Stacker with top-lifting capability is utilized to stack containers up to five high whenever required, optimizing yard space and maintaining superior operational efficiency. This setup allows for organized container management, quick accessibility, and reduced turnaround time, ensuring seamless workflow across the facility.

Additionally, the facility is equipped with 12 trolleys that can be pulled by a 5-tonne forklift, allowing ISO tank containers to be easily and safely transported to the washing bays or repair shed, ensuring streamlined handling and minimal manual intervention.